Spraywater Control Valves

Advantages

- simple design

- easy replacement of valve seat

- low actuating force

- low maintenance efforts

- actuated by any common drive types

- cost-effective

- short delivery period

Application

Valves of this type feed injection water in a controlled way to the connected fittings and/or coolers. The injection water serves as a hot-steam temperature control. To achieve a good adaptation for each application, the injection valves are available as single or multistage type. However, they can be used as control or stop valves also for other media.

Design and Function

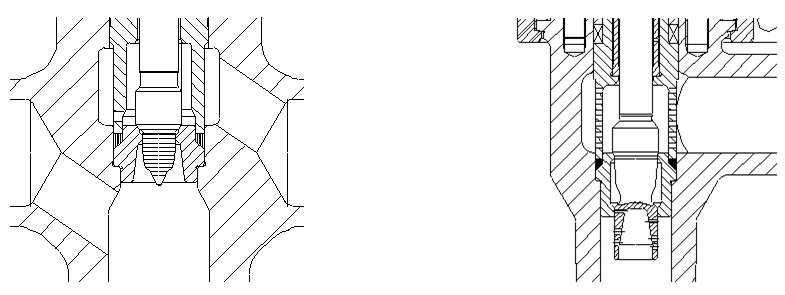

A principle of the valve design is shown in the following illustration to the left (single-stage valve type). In case of special applications, e. g. very high pressure differences, the valve is available as a multi-stage seat/cone version. The following illustration to the right shows the design of a four-stage valve.

The stable and drop-forged design of the valve casing, the wear-resistant construction of seat and cone, as well the low-friction stem sealing which can be readjusted are features to be underlined. Together with the casing seal, also the stem seal consists of pure graphite. Casing and seat seal form a static double sealing which is positioned in the line of the main power direction.

Valve cone and seat are ground-in sealed during manufacturing. During operation, these parts are protected against coarsely foreign particles by a perforated cylinder which is installed in the casing cover. To protect the unit against fine particles, we recommend installing a particle separator upstream.

Technical Data

| Design of body | E lbow | Z-type | straight pattern |

| Pressure stage | I (up to PN 400) | II (up to PN 400) | III (up to PN 400) |

| Norminal diameter | DN 15-50 | DN25-80 | DN 65-125 |

| Kvs (m³/h) | max. 11 | max. 25 | max. 72 |

| Characteristic | equal percentage (linear and square on request) | equal percentage (linear and square on request) | equal percentage (linear and square on request) |

| Seat diameter (mm) | max. 18 | max. 30 | max. 50 |

| Stem diameter (mm) | 16 | 24 | 35 |

| Stroke (mm) | 20 | 25 | 35 |

Permissible pressure difference:

All commonly used pressure differences, high pressure differences with multi-stage valve type

Gland packings:

Readjustable pure graphite stem sealing, seal for casing and seat also made of pure graphite

Connections:

Optional butt-weld ends or flange connection

Materials:

Body: 1.5415, 1.4057

Seat: 1.4057

Stem: 1.4922, 1.4903

In addition to the fitting types described above, the valves can be made of other materials and can be used for other media and different applications.

Actuator:

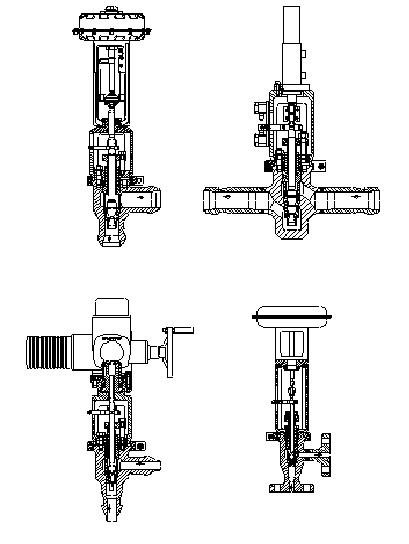

Pneumatic, hydraulic, electric with use of rotary or lever drive, handwheel

Available Design

Contact Us

Address

Armaturen Union GmbH

Erkrather Straße 401

D-40231 Düsseldorf

Germany

sales@armaturen-union.de

Phone & Fax

Tel: +49 211 5455 92 30

Fax: +49 211 5455 92 39