High Pressure Gate Valves

Design and Function

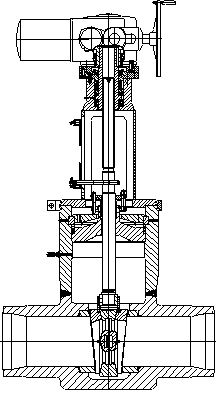

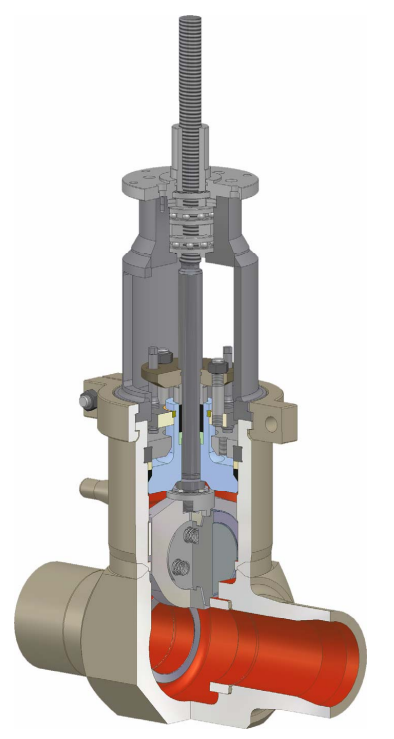

All gate valves are designed as double plate wedge gate valves or double plate parallel slide gate valves and are manufactured according to required pressure and temperature ranges. They have been in operation in large numbers for over 50 years. The pressurised parts consist of forgings which are welded to the body using only one circumferential weld seam. Our many years experience guarantees high level of technical development and safe design.

The body is forged in flow direction to form a middle section. The bonnet section is made of forged tubing and is welded to the middle section. A single circumferential welded seam enables the weld to be exactly tested by X-rays, ultrasonics or other methods. This ensures that the body has adequate strength. The valve is sealed by means of a self-sealing cover. Pressed graphite packings are used to effect the seal.

The yoke piece on top of the valve is designed in all cases as total direct drive. The stem thrust is absorbed by heavy duty axial ball bearings as well as a radial ball bearing which are fitted upon of the yoke. The stem surface is ground to size, after which it is treated by superfinishing. This ensures the most favourable conditions for sealing and sliding in the area of the stem packing.

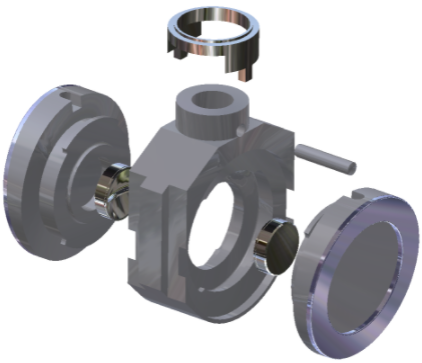

The sealing plates are suspended in a plate support so as to be self-aligning (see illustration). The pressure is transmitted by hardened ball segments and ball cups of large contact area which are inserted in the sealing discs. Sealing plates and rings are hardfaced according to the required operating conditions. Absolutely tight sealing can be achieved by relative Iow contact pressure. The gate valves can therefore be opened and closed with little effort.

It is possible to increase the spacing at the sealing plates (e. g. after grinding the sealing faces of the sealing rings) simply by inserting shims behind the ball segments.

The yoke piece on top of the valve is connected to the body by means of a two-part clamp which can be disconnected easily when dismantling or assembling. With the exception of the gland, there are no bolted connections under pressure.

All machined metal parts are protected against corrosion before delivery. The external surface of the valve is primed.

Materials

Available Design

– with welded ends,

– with flanges in accordance with DIN, ANSI or other,

– with clamp connections,

– with welded bypass connecting piece,

– with drain connection,

– with safety valve to prevent excess pressure in the body,

– with complete bypass pipe incl. globe valve,

– with sealing water gland,

– with triple gland and drainage,

– fitted with check valves,

– as wedge gate valve with parallel sealing face,

– as quick-closing gate valve,

– as quick-opening gate valve,

– with mechanical position indication,

– with special gland areas,

– with hand wheel locking,

– our gate valves can be supplied with drives (bevel or spur gear) for electric, pneumatic or

hydraulic operation.

Contact Us

Address

Armaturen Union GmbH

Erkrather Straße 401

D-40231 Düsseldorf

Germany

sales@armaturen-union.de

Phone & Fax

Tel: +49 211 5455 92 30

Fax: +49 211 5455 92 39